Sinopac Group Inc.

Sinopac Group Inc.Request A Quote

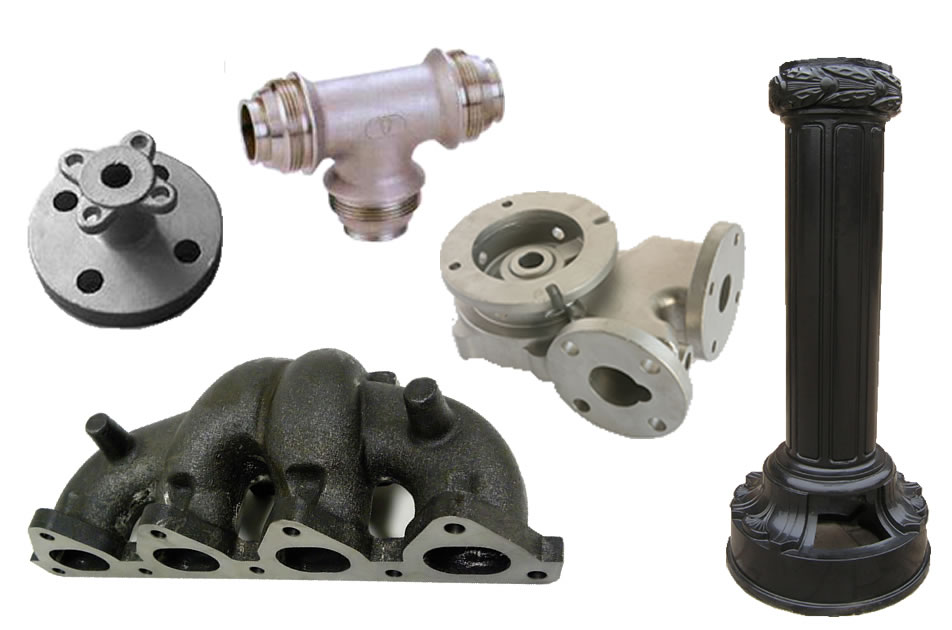

Rancho Cucamonga, CAAt Sinopac Group Inc., we specialize in producing high-quality investment castings that meet the stringent demands of industries around the globe. With decades of experience behind us, we’ve built a reputation for precision, consistency, and reliability in every casting we deliver. Our team works closely with customers from concept to completion, offering engineering support, tooling design, and metallurgical expertise to ensure each component exceeds expectations. We operate advanced foundry facilities equipped with modern wax injection, ceramic shell building, vacuum and air melting, and CNC finishing capabilities, enabling us to produce intricate and net-shape parts in a wide range of alloys. Whether it’s stainless steel, carbon steel, or heat-resistant alloys, we cast with accuracy and repeatability, even in the most complex geometries. Our castings serve critical applications across the aerospace, automotive, energy, medical, and industrial markets, and we’re proud to support both high-volume production and low-run specialty work. What sets us apart is our commitment to quality and customer satisfaction—from prototyping and testing through full-scale production and on-time delivery, we make sure every detail is aligned with our clients’ performance and cost goals.

Leading Investment Castings Companies

More Investment Castings Companies

Additional Categories: Adhesives, Air Cylinders

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services