Engineered Precision Casting Company, Inc.

Engineered Precision Casting Company, Inc.Request A Quote

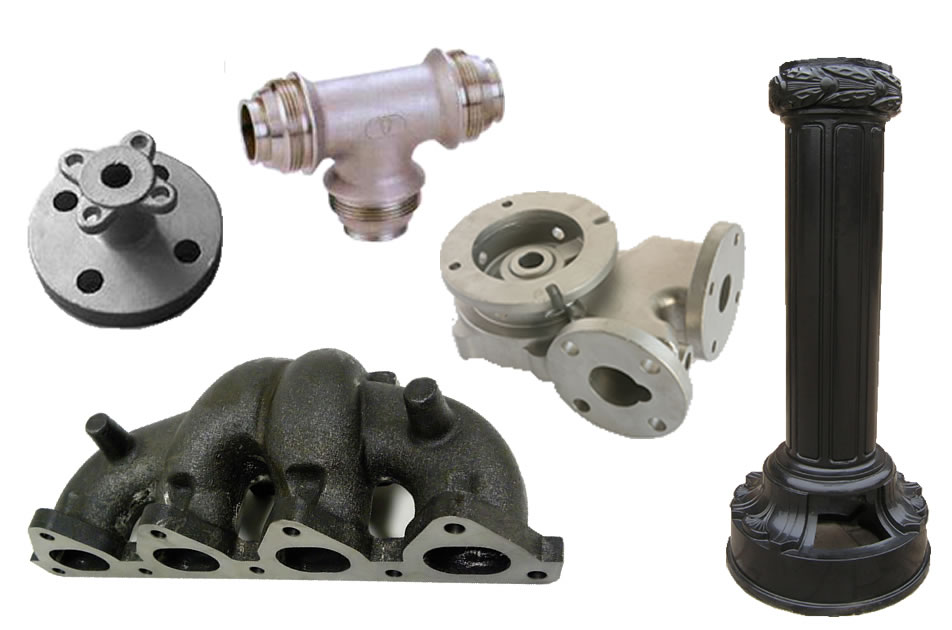

Middletown, NJ | 732-671-2424At Engineered Precision Casting Company, we specialize in producing high-quality investment castings that meet the rigorous demands of industries where precision and reliability are critical. As a team of experienced professionals, we take pride in our ability to transform complex designs into net-shape components with exceptional dimensional accuracy and superior surface finishes. Our capabilities span the entire investment casting process—from design engineering and rapid prototyping to tooling, wax pattern assembly, ceramic shell creation, metal pouring, and finishing operations—all performed in-house under strict quality control systems. We work with a wide range of ferrous and non-ferrous alloys, including stainless steels, carbon steels, nickel-based alloys, and cobalt alloys, tailoring each material to meet specific performance and application requirements. We serve clients across the aerospace, defense, medical, energy, and commercial sectors, and we understand the importance of delivering cast parts that perform under pressure in mission-critical environments. Through close collaboration with our customers, we help optimize component design for manufacturability, reduce lead times, and improve cost-efficiency without compromising quality. Whether producing small, intricate geometries or larger, more robust components, we apply the same meticulous attention to detail and commitment to excellence. By combining advanced manufacturing techniques with decades of expertise, we continue to push the boundaries of what’s possible in precision investment casting.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services