Though metal workers have several processes to choose from, this particular method of production allows for the creation of near net shape products with great detail that would otherwise be difficult or impossible to achieve with other casting methods and secondary processes such as welding and soldering. Read More…

Founded in 2011, Lodestar Quality LLC is a knowledge-driven custom manufacturing solutions provider that provides manufacturers of products a full range of services from innovative design and engineering, to sourcing and production using best in class quality control methods in a cost efficient manner. Focus areas include fabrications, castings, machining and forging, plastic products, and...

Since 1944 we have been driven to remain a cut above the competition in investment castings and everything we do. We have our own tooling shop filled with state-of-the-art testing machines. We ensure perfect results every time. It is our goal to establish lifelong relationships with our customers that benefit us both. Contact us for more info today!

At Associated MetalCast, we specialize in precision investment castings, delivering high-quality metal components with intricate geometries and superior surface finishes. Our expertise spans a range of industries, where we provide cost-effective solutions that meet tight tolerances and complex design requirements. Using advanced casting techniques and top-grade materials, we ensure durability,...

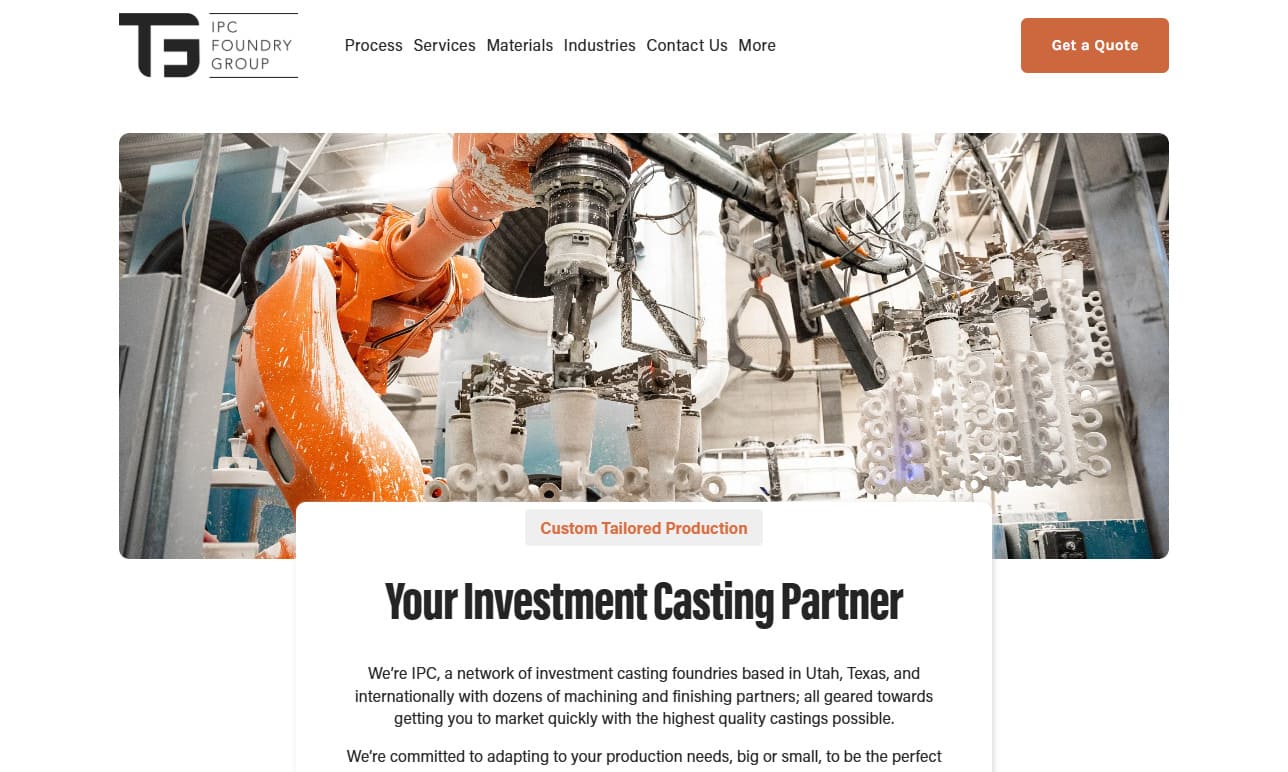

At IPC Foundry Group, Inc., we present ourselves as dedicated specialists in investment castings, producing high-precision components that meet demanding mechanical and dimensional requirements across a wide range of industries. We work with stainless steels, carbon and alloy steels, tool steels, and specialty metals, using the lost-wax process to create complex geometries with fine surface...

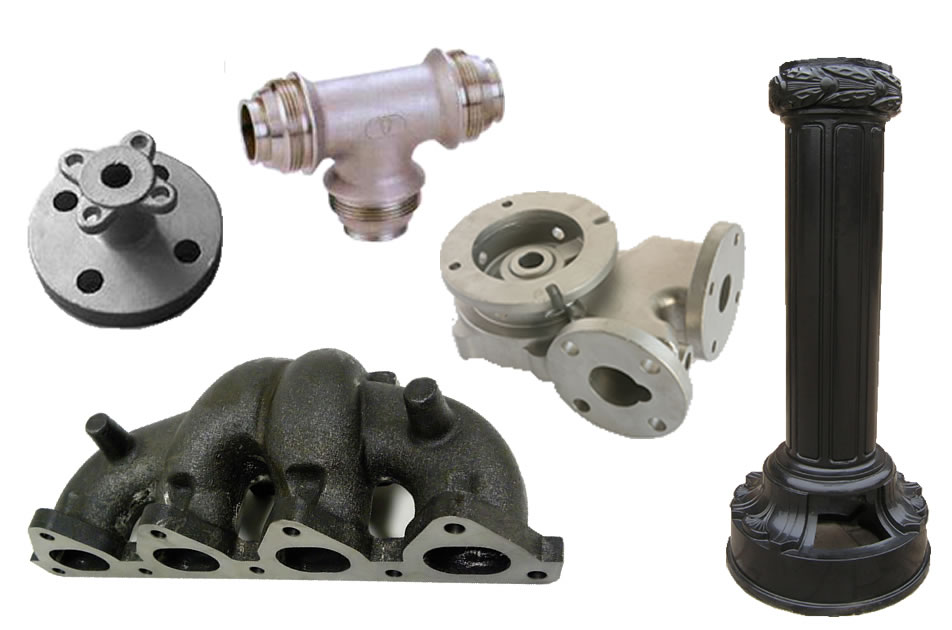

At Kormax, we present ourselves as dedicated specialists in investment castings, producing high-precision metal components that meet demanding mechanical, dimensional, and surface quality requirements. We work with a broad range of alloys—including stainless steels, carbon and alloy steels, aluminum, bronze, and specialized materials—to create castings that deliver strength, consistency, and...

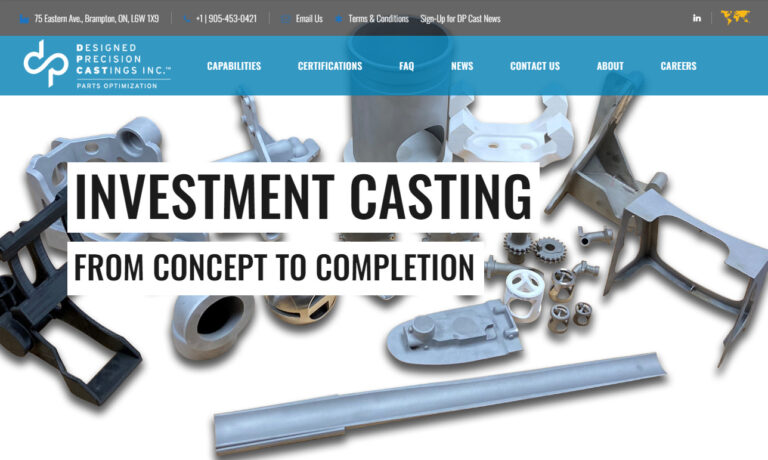

At Designed Precision Castings Inc., we present ourselves as specialists in investment castings dedicated to producing high-precision components that meet demanding mechanical, dimensional, and aesthetic requirements. We work with a wide range of alloys, including stainless steels, carbon and alloy steels, tool steels, aluminum, and specialty materials, giving us the flexibility to support...

More Investment Casting Process Companies

Investment casting is among the most basic techniques used and as such delivers reliable results at a reasonable cost, though it is not always the most economic of options. In short, this multi-step process involves forming a mold around a wax pattern and allowing it to harden before melting away the wax, leaving a hardened shell that can be filled with molten metal and removed once the desired form is sufficiently cooled.

The process is extremely versatile and with proper knowledge of the chemical formulas and molecular composition of the materials involved, manufacturers can instill specific attributes such as durability, magnetism, or weight load while diminishing or eliminating negative characteristics. Proper mechanics also allow for castings to be as small as fractions of an inch thick or as much as 1,000 pounds in weight, though most investment casting products are 15 pounds or less. Such capabilities find investment castings in the aerospace, automotive, chemical, defense, food processing, electrical, railroad, mechanical, marine, electronic, textile, engineering and several other major industries. Though relatively straightforward, the investment casting process involves a number of detailed steps.

To begin, manufacturers must create a master die or wax pattern. Though not always made of wax, this feature gives the process its alternate names of wax casting and lost wax casting. This form is an exact replica of the part to be produced. In some cases, it is the original prototype which may be either hand carved or carved by machine. It may also be made through injection molding. It is crucial that any flaws or imperfections be removed at this time and that exact specifications are met.

The master die is then mounted on a wax rod known as a sprue using a heated metal tool. Several such patterns may be attached to one sprue forming a cluster known as a tree.

The next step is to apply what is known as the investment. This ceramic slurry must coat the entirety of the wax mold. Common techniques include dipping the sprue or tree repeatedly into the investments of decreasing fineness until the desired thickness is achieved or alternately affixing the sprue in a flask and pouring the investment in around it.

Once the investment dries and hardens, it is placed upside-down in an oven or furnace, causing the wax form to melt and run out leaving the desired mold. Additional heating ensures that all residue and moisture are gone and preheats the mold allowing the incoming molten metal to coat more evenly before cooling in the mold.

Once the metal is poured into the mold it is cooled and the hardened investment shell is removed via media blasting vibrations, hammers, or a dissolving agent to reveal the seamless final product.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services