Kormax

KormaxRequest A Quote

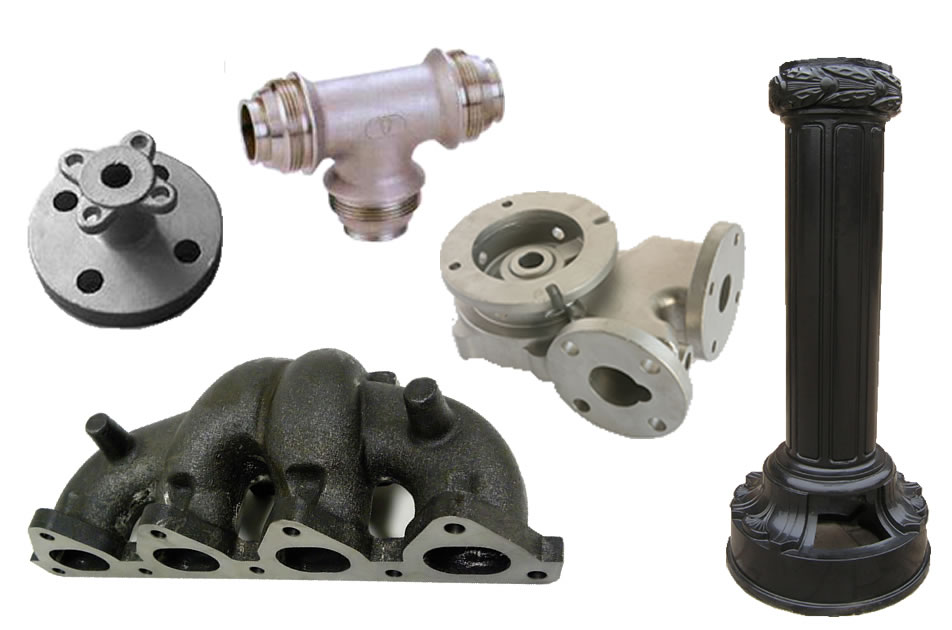

Schaumburg, IL | 708-433-4160At Kormax, we present ourselves as dedicated specialists in investment castings, producing high-precision metal components that meet demanding mechanical, dimensional, and surface quality requirements. We work with a broad range of alloys—including stainless steels, carbon and alloy steels, aluminum, bronze, and specialized materials—to create castings that deliver strength, consistency, and long-term reliability. By leveraging the accuracy of the lost-wax process and maintaining strict control over each production stage, we manufacture parts with intricate geometries, fine detail, and excellent repeatability for customers across diverse industries. We approach every project with an engineering-driven mindset, collaborating closely with customers to refine part designs, evaluate alloy options, and determine gating and tooling strategies that optimize manufacturability and performance. Our capabilities encompass rapid prototyping, pattern production, ceramic shell building, controlled melting and pouring, heat treatment, machining, and finishing operations that prepare each casting for seamless integration into downstream processes. Through chemical analysis, mechanical testing, dimensional inspection, and microstructure evaluation, we verify that every component meets the highest standards for quality and structural integrity.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services