Lost wax casting is a process that uses a wax pattern to produce a ceramic mold for making a product or part design. The process is also called precision casting because of its high accuracy and precise tolerance in recreating parts. Read More…

Founded in 2011, Lodestar Quality LLC is a knowledge-driven custom manufacturing solutions provider that provides manufacturers of products a full range of services from innovative design and engineering, to sourcing and production using best in class quality control methods in a cost efficient manner. Focus areas include fabrications, castings, machining and forging, plastic products, and...

Since 1944 we have been driven to remain a cut above the competition in investment castings and everything we do. We have our own tooling shop filled with state-of-the-art testing machines. We ensure perfect results every time. It is our goal to establish lifelong relationships with our customers that benefit us both. Contact us for more info today!

At Associated MetalCast, we specialize in precision investment castings, delivering high-quality metal components with intricate geometries and superior surface finishes. Our expertise spans a range of industries, where we provide cost-effective solutions that meet tight tolerances and complex design requirements. Using advanced casting techniques and top-grade materials, we ensure durability,...

At IPC Foundry Group, Inc., we present ourselves as dedicated specialists in investment castings, producing high-precision components that meet demanding mechanical and dimensional requirements across a wide range of industries. We work with stainless steels, carbon and alloy steels, tool steels, and specialty metals, using the lost-wax process to create complex geometries with fine surface...

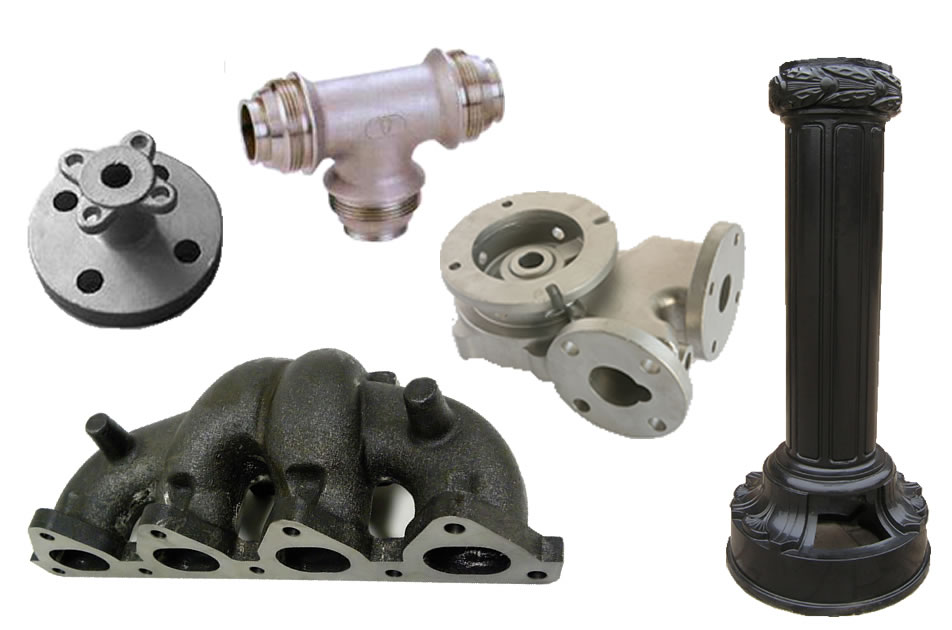

At Kormax, we present ourselves as dedicated specialists in investment castings, producing high-precision metal components that meet demanding mechanical, dimensional, and surface quality requirements. We work with a broad range of alloys—including stainless steels, carbon and alloy steels, aluminum, bronze, and specialized materials—to create castings that deliver strength, consistency, and...

At Designed Precision Castings Inc., we present ourselves as specialists in investment castings dedicated to producing high-precision components that meet demanding mechanical, dimensional, and aesthetic requirements. We work with a wide range of alloys, including stainless steels, carbon and alloy steels, tool steels, aluminum, and specialty materials, giving us the flexibility to support...

More Lost Wax Casting Companies

Metals Used In Lost Wax Casting

Stainless Steel

Stainless steel consists of alloys such as nickel and chromium, which determine the mechanical and grain properties of the casting. The combination of the alloys affects the endurance of heat and resistance to corrosion by the casting. However, stainless steel has a percentage of chromium, making it resistant to oxidation and corrosive conditions.

Steel

Steel is used for lost wax casting because it is available in various grades, is economical, and can be heat treated to adjust its ductility. Its application can be found in the medical, aerospace, agricultural, and firearm sectors.

Ductile Iron

Ductile iron castings have excellent corrosion resistance, surface hardness, strength-to-weight ratio, and elasticity modulus. Its main advantage is that it has multiple designs and is cost-effective.

Beryllium Copper

Beryllium copper makes castings that can be easily machined and have great ductility. After heat treatment, beryllium copper has excellent electrical and thermal conductivity.

Aluminum

Aluminum is considered an ideal metal for lost wax casting because of its resistance to corrosion and machinability. When aluminum is alloyed and heat treated with other metals, it develops excellent strength, like that of low carbon steel. Aluminum alloys have a fluid nature that caters to parts with thin walls.

Cobalt

Cobalt has a lustrous and hard finish that protects it and makes it resistant to oxidation. Cobalt is not affected by oxidation due to a passivating film that covers it. Since cobalt is found combined within nature, the smelting process is used to separate it from alloys. Cobalt is ideal for the process of lost wax casting because it is worn, corrosion, and heat resistant. It is used to make parts for the automotive industry, aerospace, and military use.

Brass

Brass's main defining properties are its polishing and finishing qualities. Yellow or red brass is used for lost wax casting for application and in door hardware and plumbing fixtures.

Bronze

The added elements of bronze enhance bronze's quality and performance. For example, aluminum and manganese can be added to make it corrosion-resistant.

Nickel

Nickel has great strength and resistance to heat, so nickel alloys are used in environments with extreme temperatures. Their use is found in chemical factories, aerospace, and marine environments.

The Lost Wax Casting Process

Rendering the Wax Pattern

The first step in the lost wax casting process is the formation of a three-dimensional rendering of what needs to be produced. Then, a die that is a negative relief to the part is created.

Producing the Wax Pattern

A wax pattern is formed from the semi-liquid wax poured into the die. Next, it is adjusted to make room for shrinkage. The process can be done several times depending on the parts that must be cast. The wax pattern is then connected, forming a sprue and later a cluster. These are known as a tree.

Shell Building and Dewaxing

The pattern is put in a ceramic slurry to build a shell. The shell creates a hard exterior coating surrounding the pattern. Next, the wax inside the ceramic shell must be removed by putting the ceramic shell in an oven.

Burnout and Casting

Burnout is a procedure carried out to remove residual moisture and wax. The casting process will involve pouring the molten metal into the ceramic mold.

After the casting, the cleaning and divesting procedures are followed by cutting the finished part, usually with a grinder. Finally, the part can be sandblasted before it undergoes surface treatments and is ready for use.

Applications of Lost Wax Casting

The industries lost wax casting are used in include:

- Aerospace

- Automotive

- Oil and gas

- Chemical

- Food

- Medical

Advantages of Lost Wax Casting

- Affordable tooling

- Accurate tolerances

- Great range of sizes

- Low production cost

Choosing the Right Lost Wax Casting Manufacturer

To make sure you have the most productive outcome when purchasing Lost Wax Casting from a Lost Wax Casting Supplier, it is important to compare at least 4 or 5 Companies using our Lost Wax Casting directory. Each Lost Wax Casting Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Lost Wax Casting company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Lost Wax Casting businesses with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services