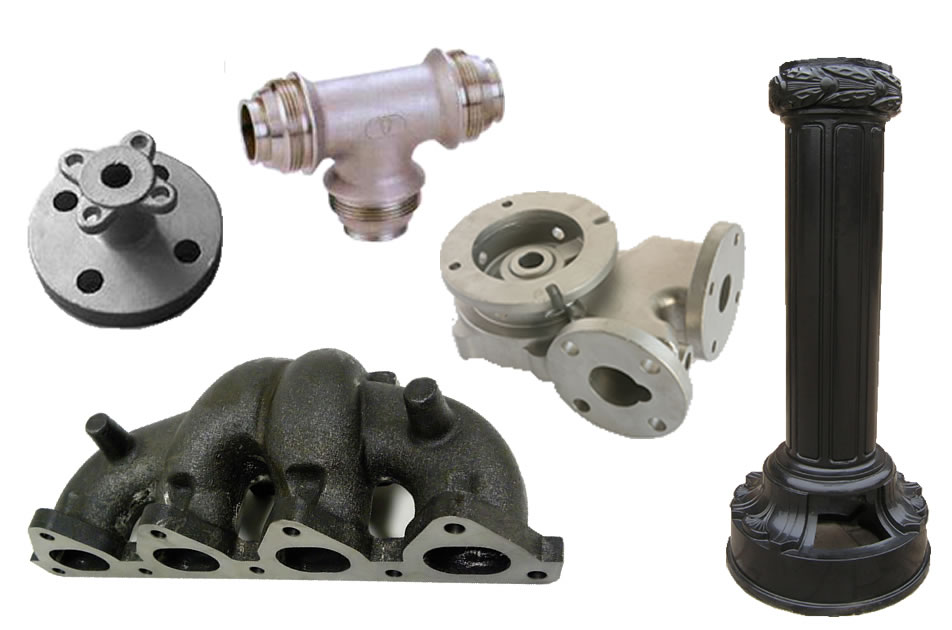

A wide range of parts can be created by the investment casting process. Industrial products, commercial products and even consumer products are regularly produced by investment casting operations. Typically, investment casting is used for the creation of products with complex profiles in comparatively limited quantities. This can make investment casting somewhat more expensive than other metal forming processes. However, investment casting also produces products that require minimal surface finishing, and it can create products with more precision than other metal forming varieties.

The investment casting process is capable of producing products with such tight tolerances because of the nature of the process. It is a meticulous process, but this means that it can create products with high accuracy. The process begins when an engineer designs a wax pattern on which the shape of the final investment cast product is based. This pattern is identical to the final cast product except in its composition. When the pattern is satisfactorily completed, it is coated in several layers of ceramic materials, which are then allowed to harden. When the ceramic hardens to the desired extent, the original wax pattern around which the ceramic has formed is melted and discarded. At this point, some variety of molten metal is invested into the ceramic shell. Metals that are often investment cast include aluminum, steel, stainless steel, copper, nickel, brass and to a lesser extent zinc and titanium.

Once the molten metal has fully taken shape within the ceramic shell, it remains there until it cools and hardens. At this point, the ceramic shell around the newly investment cast product is removed. This can be accomplished in many ways; one common method involves vibrating the product until the shell crumbles away. Because investment casting products are produced on small scales in this way, their products can be somewhat more expensive than the products of other kinds of metal forming process. However, as mentioned earlier, the trade-off is that products of investment casting processes are precise and of very high quality.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services