Iron is the most prominent element in steel alloys, with carbon coming in second. Additional elements such as manganese, chromium, vanadium, and tungsten may be included in steel investment castings. Read More…

Founded in 2011, Lodestar Quality LLC is a knowledge-driven custom manufacturing solutions provider that provides manufacturers of products a full range of services from innovative design and engineering, to sourcing and production using best in class quality control methods in a cost efficient manner. Focus areas include fabrications, castings, machining and forging, plastic products, and...

Since 1944 we have been driven to remain a cut above the competition in investment castings and everything we do. We have our own tooling shop filled with state-of-the-art testing machines. We ensure perfect results every time. It is our goal to establish lifelong relationships with our customers that benefit us both. Contact us for more info today!

At Associated MetalCast, we specialize in precision investment castings, delivering high-quality metal components with intricate geometries and superior surface finishes. Our expertise spans a range of industries, where we provide cost-effective solutions that meet tight tolerances and complex design requirements. Using advanced casting techniques and top-grade materials, we ensure durability,...

At IPC Foundry Group, Inc., we present ourselves as dedicated specialists in investment castings, producing high-precision components that meet demanding mechanical and dimensional requirements across a wide range of industries. We work with stainless steels, carbon and alloy steels, tool steels, and specialty metals, using the lost-wax process to create complex geometries with fine surface...

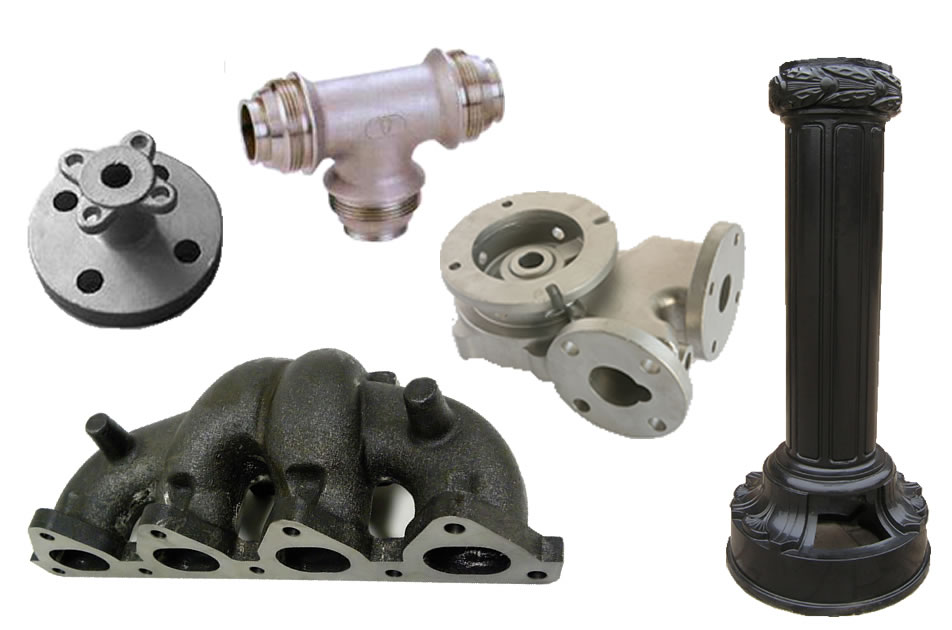

At Kormax, we present ourselves as dedicated specialists in investment castings, producing high-precision metal components that meet demanding mechanical, dimensional, and surface quality requirements. We work with a broad range of alloys—including stainless steels, carbon and alloy steels, aluminum, bronze, and specialized materials—to create castings that deliver strength, consistency, and...

At Designed Precision Castings Inc., we present ourselves as specialists in investment castings dedicated to producing high-precision components that meet demanding mechanical, dimensional, and aesthetic requirements. We work with a wide range of alloys, including stainless steels, carbon and alloy steels, tool steels, aluminum, and specialty materials, giving us the flexibility to support...

More Steel Investment Casting Companies

The strength and durability of a particular casting is largely dependent upon the specific metallurgical composition. In general, steel and especially stainless steel investment casting are popular in industrial applications as they are stronger than cast iron, wrought iron, and malleable iron. These parts are capable of enduring shocks, wear, and heavy loads.

Though these features can be attributed in large part to the material itself, investment casting allows for the creation of completed precision parts with no flash or parting lines. Because the wax molds are exact replicas of the desired final product, accuracy is easily attained and parts rarely require additional processing.

Because steel investment castings are used in such varied industries as aerospace, automotive, construction, dental, medical, military, mining, food processing, sports, and telecommunications; it is important to consider the design and material used to create a specific component to ensure it is suited to its intended use.

When ordering steel investment castings, the type of steel that will be used to produce the part must be identified. Steel investment castings are usually ordered to ASTM requirements and may be made from carbon steel, low and high alloys steel, low-temperature steel, heat resistant steel, and stainless steel, among others. By specifying the test methods for an order, the requirements of the material can be guaranteed.

Though the material composition of the steel is variable, the investment casting process is relatively straightforward.

First, a wax pattern is carved by hand, machine, or created through injection molding. This model is often a prototype and must meet the exact specifications of the finished part.

The wax master die is then mounted on a wax rod known as a sprue. In some cases several dies are attached to a single sprue creating what is known as a tree.

The assembly is then dipped into a ceramic slurry known as the investment until thoroughly covered. For particularly complex designs, the sprue may be placed in a flask that is then filled with investment and vibrated to remove air pockets and ensure complete adherence to the pattern.

This coating is then dried and hardened using an oven or furnace which also melts the wax. Additional heating may be required to remove moisture or wax residue. As the wax runs out, a hollow shell is left.

Molten steel is poured into it. Once the steel is fully cooled the shell is removed by water-blasting, dissolving agent, or other method to reveal the finished steel product.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services