Titanium investment casting is a manufacturing process that creates parts through the metallic replication of wax models. The produced titanium parts have a smooth finish that requires little finishing after the process. This casting process is ideal for producing complex and detailed parts that other methods cannot. Read More…

Founded in 2011, Lodestar Quality LLC is a knowledge-driven custom manufacturing solutions provider that provides manufacturers of products a full range of services from innovative design and engineering, to sourcing and production using best in class quality control methods in a cost efficient manner. Focus areas include fabrications, castings, machining and forging, plastic products, and...

Since 1944 we have been driven to remain a cut above the competition in investment castings and everything we do. We have our own tooling shop filled with state-of-the-art testing machines. We ensure perfect results every time. It is our goal to establish lifelong relationships with our customers that benefit us both. Contact us for more info today!

At Associated MetalCast, we specialize in precision investment castings, delivering high-quality metal components with intricate geometries and superior surface finishes. Our expertise spans a range of industries, where we provide cost-effective solutions that meet tight tolerances and complex design requirements. Using advanced casting techniques and top-grade materials, we ensure durability,...

At IPC Foundry Group, Inc., we present ourselves as dedicated specialists in investment castings, producing high-precision components that meet demanding mechanical and dimensional requirements across a wide range of industries. We work with stainless steels, carbon and alloy steels, tool steels, and specialty metals, using the lost-wax process to create complex geometries with fine surface...

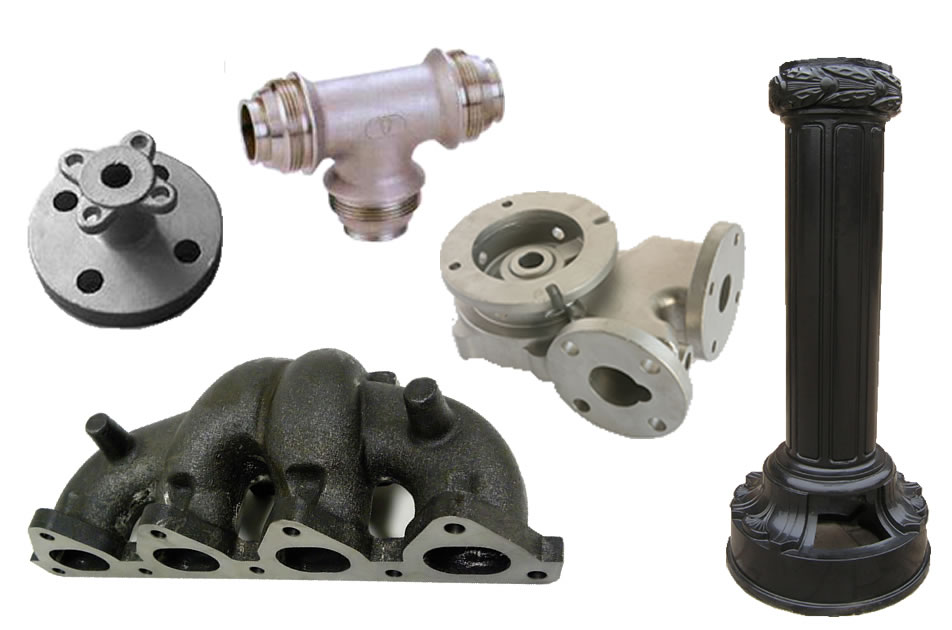

At Kormax, we present ourselves as dedicated specialists in investment castings, producing high-precision metal components that meet demanding mechanical, dimensional, and surface quality requirements. We work with a broad range of alloys—including stainless steels, carbon and alloy steels, aluminum, bronze, and specialized materials—to create castings that deliver strength, consistency, and...

At Designed Precision Castings Inc., we present ourselves as specialists in investment castings dedicated to producing high-precision components that meet demanding mechanical, dimensional, and aesthetic requirements. We work with a wide range of alloys, including stainless steels, carbon and alloy steels, tool steels, aluminum, and specialty materials, giving us the flexibility to support...

More Titanium Investment Casting Companies

The part is made as one whole piece resulting in the absence of joints or flash lines. Titanium castings are very strong and lightweight. They are used for turbocharger components, industrial tools and instruments, and other applications in the defense, aerospace, transportation, power generation, marine, and medical industries. However, this investment casting is expensive compared to other methods such as die casting.

Nevertheless, titanium investment casting has lower equipment costs and requires less finishing. Investment casting can be carried out by hand in single or small batches, resulting in hundreds of parts at once.

How Titanium Investment Casting Functions

The process of investment casting starts with a wax replica of the part that has been hand or machine carved through injection molding. The wax pattern is connected to a sprue. Numerous patterns can be connected to the same sprue, resulting in an assembly called a tree. This connection depends on the side and shape of the part used. The tree is placed in a ceramic slurry called the investment. Then, it is dipped several times in increasingly coarse mixtures.

The tree is left to dry when the investment is thick enough on the wax pattern. Another method is to insert the tree in a flask and pour investment into the container until the tree is completely covered. Molten titanium is poured into the space and can be supplied through a vacuum. The investment is removed using numerous ways, such as vibrations or hammers, once the titanium part is cooled and hardened.

Types of Titanium Investment Casting

Different types of titanium investment casting are made to advance the method for developing the pattern. The materials used to create the pattern and their production differ significantly in these types.

Lost Foam Casting

Lost foam casting is now being used regularly due to its ability to fit into mass production and automated processes. This process was developed to enable polystyrene foam to be placed in casting sand. An aluminum die is used to create the pattern, and polystyrene beads are injected into the mold for heating. This process results in the beads melting and attaining the shape of the mold.

As the heating continues, the beads expand to replicate the dimensions and contours of the die. Finally, singular patterns are connected to a sprue and sprayed using a refractory coating of ceramic material. This type of investment casting can be used to create ornate, decorative, and complex metal configurations.

Direct Investment Casting

Direct investment casting is different from traditional investment casting because of how the pattern is created. Traditional casting creates the pattern in a die to form a wax representation. Wax duplicates are connected to a sprue and then dipped in a ceramic solution. Wax is later removed for the pattern to be filled with molten metal.

Direct casting is unique in the way the pattern is formed with various techniques. The first technique is carving the pattern by hand or machine to create a one-up version. This version is processed using the lost wax method. This process involves prototype production and assessment of dimensions for finished parts. Then, with CAD, a three-dimensional representation of the workpiece is created and designed. In relation to this, STL is a method for fabricating a solid shape using a photosensitive liquid polymer and a directed laser beam.

Water Glass Investment Casting

In this process, a water glass is used as the binding agent for the shell. Water glass investment casting has the advantages of material costs and production cycle. In addition, the surface finishes from water glass investment casting avoid defects found in traditional shell technology.

This type has processes that are less complicated and can be carried out by untrained workers. This factor results in improved production and efficiency.

Applications and Uses

The resulting titanium from titanium investment casting is used in the airline industry for assembling engine parts. In the biomedical field, titanium is used for dental implants because of its high strength-to-weight ratio. Finally, for military purposes, titanium invested casting parts are used for naval ships.

Choosing the Correct Titanium Investment Casting Supplier

To make sure you have the most constructive outcome when purchasing Titanium Investment Casting from a Titanium Investment Casting Supplier, it is important to compare at least 4 Companies using our Titanium Investment Casting directory. Each Titanium Investment Casting Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Titanium Investment Casting company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Titanium Investment Casting companies with the same message.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services